A sealant fit for the future

Sealing the earth with less impact.

- Glue is one of the oldest do-it-yourself fixes in history

- We challenged our researchers to create a new type of sealant

- We tested the first-ever water-based sealant in the industry

A next-gen glue just might come from your faucet one day. At Saudi Aramco, it already does. Glue is one of the oldest do-it-yourself fixes in history.

In 70,000 BC, plant and animal products were mixed together to seal and protect cave drawings. In 4,000 BC, broken ceramics became whole again thanks to glue, and ancient Egyptians were the first to use it to assemble furniture.

Fast forward to 2019.

Today, glue is as essential in the classroom as it is to some of the world’s largest industrial projects. In energy, an especially important use of glue is in sealing cracks that develop in cement that cases a well.

Think of a well this way: It’s a narrow, boredout hole into the Earth, downhole, as it is called, that draws hydrocarbons and gas to the surface. Sometimes the cement can develop cracks.

To fix it, like those who came before us, we turned to glue.

In 2017, we tested the first-ever water-based sealant in the industry in fields in Saudi Arabia.

A new type of sealant

At Aramco, we challenged our researchers to create a new type of sealant, to use advanced science to dream up a modern solution — with reduced impacts on the Earth and the greatest impact in terms of strength and durability.

We set our sights on water, as natural as you can get and critical to life.

We are not alone in this effort.

The energy industry has long considered using water as a building block in sealants. A water-based sealant could reduce or eliminate chemicals in casing-in-casing annular events, the technical term for cracks that can occur in wells.

At Aramco, we challenged our researchers to create a new type of sealant, to use advanced science to dream up a modern solution.

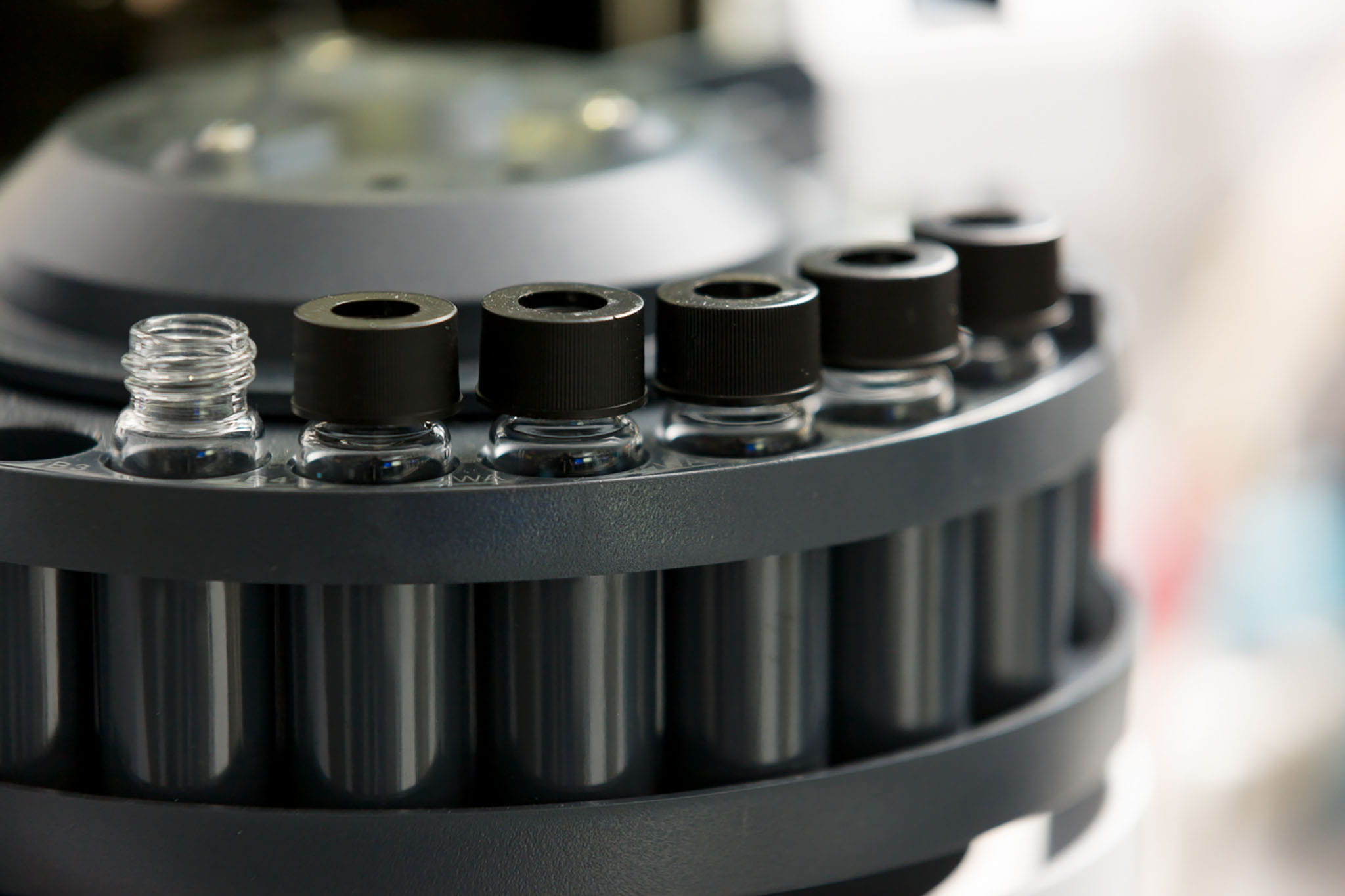

Our scientists got to work in the lab, and before long, found a way to use water and chemistry to engineer a new kind of sealant. In 2017, we tested it — the first-ever water-based sealant in the industry — in Saudi Aramco’s fields in Saudi Arabia. Called ArcResin, it was a success over other commercial products.

"We plan for the next generation of ArcResin to be effective up to a temperature of 350 degrees Fahrenheit, which is substantially higher than what today’s chemically-based sealants can withstand,” said Elizabeth Contreras, a research scientist with the Drilling Technology Team at the Aramco Research Center-Houston. “ArcResin also performs better in high-pressure applications, which is critical for deep-water offshore activities.”

In 2018, ArcResin was named a finalist for the World Oil Awards in the category of Best Health, Safety, Environment/Sustainable Development Offshore. Aramco holds multiple patents on this technology and plans are underway to apply the latest generation of ArcResin in our fields in Saudi Arabia.

Meet one of the scientist’s behind ArcResin

Elizabeth Q. Contreras is a research scientist, at our Aramco Research Center-Houston. She, along with scientists and engineers in offices in Dhahran, Saudi Arabia, were among the team responsible for ArcResin.

Contreras received her Ph.D. in organic chemistry from Rice University, a master’s in chemistry and chemical biology from Cornell University, and a bachelor’s in chemistry from Texas A&M-Corpus Christi. She said a high school chemistry class inspired her lifelong interest in chemistry.